WHAT IS SVR 3l (TSR 3L) NATURAL RUBBER?

APPLICATIONS

In order to meet the products of L or 3L grade, it must satisfy important characteristics such as Po, color (Lovibond), dirt content, storage … in standard TCVN 3769: 2016.

With high PO parameter characteristics (PO> 35), SVR 3L natural rubber products are applied to products that require high elasticity as well as high abrasion resistance.

Common applications of SVR 3L natural rubber include car tires, belts, power cables, bicycle guts, washers, other rubber parts in cars, etc.

Another key point, SVR 3L is also used in products that need light color high quality straps, cables, shoe soles, medical products, electronics industry, high quality products in the medical industry…

Light color

High level of purity

High elasticity and elongation

Good aging resistance

SVR 3L QUALITY SPECIFICATIONS ACCORDING TO TCVN 3769:2016

In particular, SVR 3L is also known as block rubber is graded according to precise technical parameters such as dirt content, ash content, nitrogen content, volatile matter and properties of the rubber such as its Wallace Plasticity (PO) and its Plasticity Retention Index (PRI).

Dirt content (max% wt), retained on 45 micron sieve: 0,03

Ash content (max % wt): 0,50

Nitrogen content (max % wt): 0,60

Volatile matter (max % wt): 0,80

Initial plasticity ( Po ) (min): 35

Plasticity retention index (PRI) (min): 60

Lovibond Color I Index (max) Difference between samples (max):

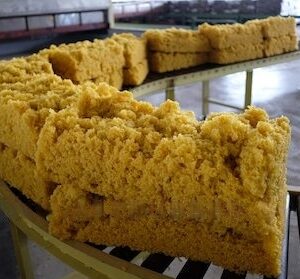

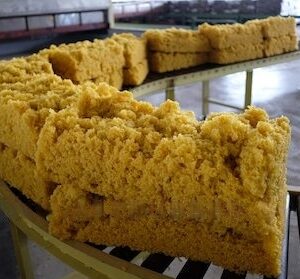

PRODUCTION PROCESS OF NRCL RUBBER

SVR 3L is produced entirely from latex of garden plants according to Cameroonian standards (TCVN: 3769). Firstly, latex is preserved by ammonia or sodium sulfite. Then the rubber is then coagulated with formic acid, followed by shredding by passing through a rolling mill, washing system and hash. After the crumb rubber is dried, it will be compressed into blocks and packed in polyethylene bags. SVR 3L rubber is a light colored rubber with a low content of dirt and odorless.

Finally, our SVR 3L rubber processing production line is supplied and maintained periodically by a reputable company in the mechanical industry, manufacturing production lines and water treatment systems. waste in Cameroon rubber industry.

Reviews

There are no reviews yet.